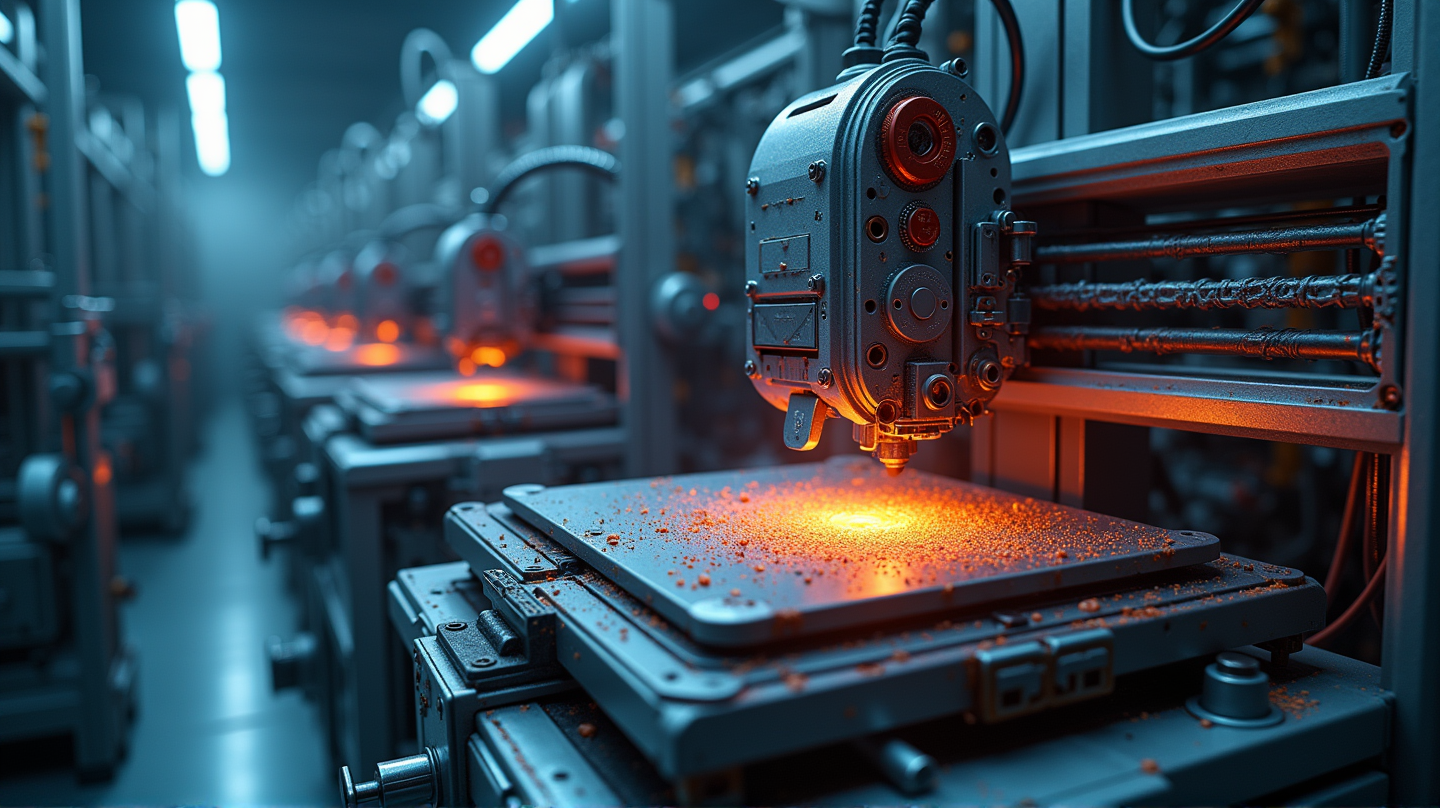

Titanium Additive Manufacturing: A Symbol for Future Industry Growth

The Titanium Additive Manufacturing market is accelerating toward an 18% CAGR by 2030, driven by aerospace and medical advances.

Titanium additive manufacturing is reshaping industries such as aerospace and medicine with cutting-edge technologies and an 18% CAGR forecasted through 2030. As stated in macholevante.com, understanding the magnitude of these changes offers insight into the bustling future of advanced manufacturing.

The Dawn of Titanium Additive Manufacturing

The era of complex geometries and high-performance components crafted via titanium additive manufacturing is upon us. Here, titanium’s unique properties, such as high strength-to-weight ratio and biocompatibility, are becoming invaluable to several sectors. The aerospace industry remains a frontrunner, utilizing titanium for lightweight and durable aircraft components, while the medical field leverages its potential for patient-specific devices.

Innovations Fueling Market Growth

Drawing from the latest advancements, additive manufacturing is surging with key innovations:

- Powder Bed Fusion Refinements: Enhancing speed and precision, companies like GE Additive continue breaking boundaries in high-resolution titanium production.

- Binder Jetting Alternatives: Pioneers are venturing into this method for economical high-volume production, promising affordability without sacrificing quality.

- Novel Alloy Developments: Innovations in titanium alloys, such as Ti-5553, spearheaded by industry leaders, pave the way for broader applications.

Regional Dynamics and Growth Doubling

Regions like North America and Europe are adapting rapidly, with technology integration at the forefront of operations, while Asia-Pacific emerges as a high-growth area due to increasing investments in technology and infrastructure developments.

Strategic Partnerships and Sustainable Dynamics

Strategic alliances among OEMs, material providers, and end-users are key to unlocking further potential in this evolving market. Companies are investing in sustainability by recycling titanium powders, showcasing the importance of creating a circular economy within the additive sector.

Opportunities Amidst Challenges

The titanium additive industry finds itself at a strategic crossroads, balancing immense growth potential with notable challenges, including powder costs and regulatory hurdles. However, the strides in innovation offer promising solutions.

Looking Ahead: Future Applications and Innovations

Emerging sectors such as energy are exploring titanium AM for demanding applications like heat exchangers and turbines. Meanwhile, digital transformation and standardized practices across geographies promise a landscape filled with unexplored opportunities.

In conclusion, as we witness the titanium additive manufacturing sphere unfold, its influence on traditional manufacturing processes and new industry checkpoints highlights a dynamic journey filled with potential for innovation and economic reinforcement.